ROBOTICS

/ APPLICATION FIELD ROBOTICS

Robotic applications open up whole new possibilities for industrial production. They increase the flexibility and efficiency of manufacturing processes, execute complex machining processes without getting tired and can be used in working environments that are unsuitable for humans. However, manufacturing robots also deliver excellent results only with powerful tools and tool drives. SycoTec therefore offers a wide range of motor spindles in the power range from 1,050 to 5,000 W and thus the right drive for your needs

Spindles for all applications

A KUKA robot with SycoTec drive was on display at EMO 2017 in Hanover. It represents the many possible applications of our spindles in robot-assisted production, ranging from simple solutions for materials that can be easily machined, such as the milling of aluminium profiles, to high-performance drives for the machining of hard and tough composite materials.

Maximum flexibility

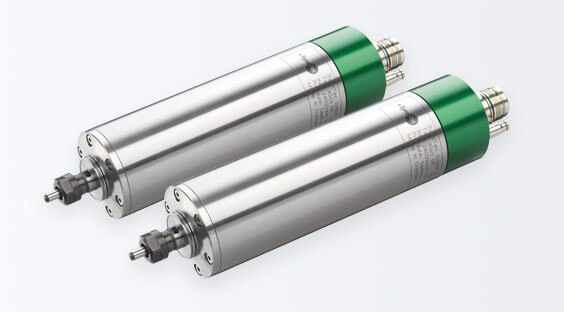

For applications with changing task profiles, our 4060 ER and 4060 ER-S spindles provide you with a drive that has sufficient power reserves, is easy to install and compatible with all standard drives. Both spindles are noted for their above-average power density. Their low weight also allows them to be used on smaller robot arms and, together with SycoTec’s customer-specific adaptation options, makes them one of the most flexible drive solutions available on the market.

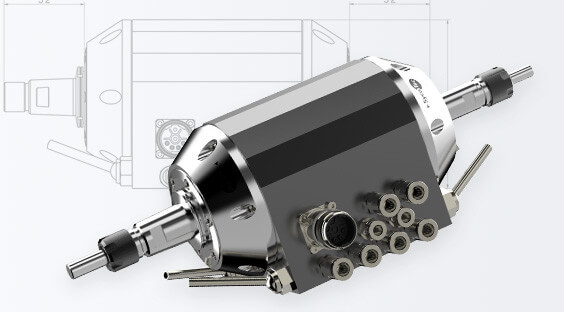

One drive, two tool holders

Our high-frequency motor spindle 50100 AC-duo also lives up to the requirements of flexible production in a special way: It has two tool holders and can perform two different machining steps with them, without the need to change tools. The motor spindle provides the considerable power of 3 kW. It achieves a torque of up to 1 Nm and a maximum speed of 50,000 rpm.